Dealing with a Fanuc CNC machine can be complex, especially when troubleshooting alarms. One common issue is Alarm F on the Alpha I servo amplifier, indicating a failure of the external cooling fan mounted on the heatsink. This guide will help you understand the causes of this alarm and provide step-by-step instructions on how to resolve it.

Encountering Alarm F on a Fanuc CNC machine can be challenging due to the complicated nature of CNC systems and the critical role servo amplifiers play in machine operations. The Alpha I servo amplifier, essential for precise control of motor functions, relies heavily on effective cooling to maintain optimal performance. The amplifier can overheat when the external cooling fan fails, leading to potential machine shutdowns or degraded performance. This comprehensive troubleshooting guide delves into the technical intricacies of Alarm F, exploring the root causes such as fan motor failure, obstruction of airflow, and electrical issues.

Let’s look at a detailed, systematic approach to diagnosing and resolving the issue, including inspecting the fan for physical damage, ensuring proper electrical connections, and verifying system parameters. Additionally, we will cover preventive maintenance tips to avoid future occurrences and enhance the longevity of your CNC machinery. By following these expert guidelines, you can minimize downtime, maintain precision in your machining operations, and ensure the reliability of your Fanuc CNC system.

Understanding Alarm F on Fanuc Servo Amplifiers

What is Alarm F?

Alarm F on the Alpha I servo amplifier indicates a failure of the external cooling fan on the heatsink. This alarm progresses in two stages:

- Warning State: Initially, the amplifier detects a fan problem and goes into a warning state.

- Alarm State: If the fan issue is not corrected within one minute, the amplifier enters the alarm state, and the machine becomes non-operational.

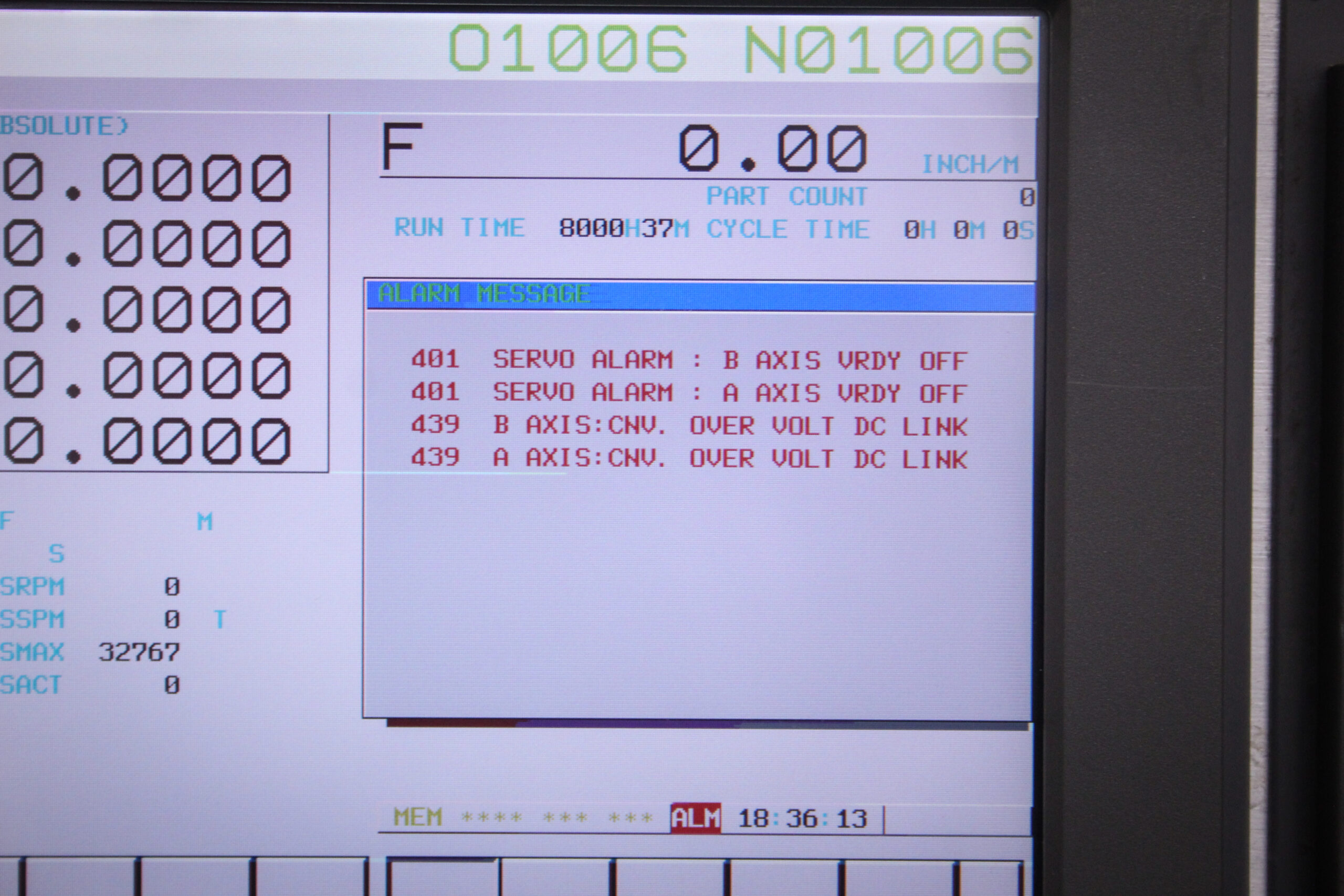

Related Alarms: DS609 and SV601

- DS609 Alarm: The CNC generates this alarm when it detects the servo amp in a warning state. The alarm specifies the affected axis.

- SV601 Alarm: This indicates that the amplifier has moved into the alarm state due to the fan issue, causing all amplifier units to become not ready, and the machine can no longer move.

Troubleshooting Steps

1. Initial Diagnostics

- Check Status Displays: With the machine powered on, access the electronics cabinet safely and look for the unit displaying an F. This indicates the faulty amplifier.

2. Safety Precautions

- Follow Safety Procedures: Always follow plant safety and lockout procedures before maintenance. Release all energies related to the maintenance procedure.

- Electrical Cabinet Precautions: Opening the cabinet with power applied can be dangerous. Ensure you are fully qualified and have permission from the equipment owner.

3. Identifying the Problem

- Check for Radiator or Heatsink Issues: Depending on the software version, the CNC alarm might refer to a “radiator.” This is the same as the heatsink mounted on the back of the servo amplifier.

- Inspect the External Fan: Located on top of the heatsink, the external fan may be blocked or filthy. Cleaning it might resolve the issue.

4. Removing the Servo Amplifier

- Determine Amplifier Model: Newer models allow fan removal without uninstalling the amplifier. Check by removing the internal fan first. If you see yellow plastic, you can remove the fan without uninstalling the amplifier.

- Loosen Screws: For older models, you might need to remove the amplifier to access the external fan. Use a Japanese Industrial Standard (JIS) tipped screwdriver to avoid stripping the screw heads.

5. Accessing the External Fan

- Removing the Internal Fan: The internal cooling fan lifts off after squeezing two tabs. This provides access to inspect the back wall of the servo amplifier.

- Loosening Screws: Loosen the screws holding the external fan in place. Ensure the DC-Link is entirely discharged to avoid electrical hazards.

6. Troubleshooting the Fan

- Inspect for Blockages: Ensure the fan is not physically blocked or excessively dirty.

- Reseat Fan Modules: Check for bad connections and reseat the fan modules if necessary.

- Check Logic Board Connections: The signals for the external fan rely on the internal fan. Reseat the logic board on the front of the amplifier to ensure a good connection.

7. Replacing the Fan

- Identify Part Numbers: The fan’s part number usually starts with A90L. If not visible, provide the A06B number from the servo amplifier’s label to your parts supplier.

- Replace the Fan: If troubleshooting steps do not resolve the issue, replace the external fan. If the problem persists, it might be due to the amplifier itself.

8. Additional Tips

- Parameter 1807: Setting bit 2 to 1 in parameter 1807 can prevent the DS609 alarm from occurring. This gives you a minute to move the machine while the amplifier is in a warning state.

- Fan Speed Diagnostics: Newer amplifiers have diagnostics that report the fan speed (Diagnostic 1714 for single fans and Diagnostic 1715 for dual fans).

Successful Troubleshooting and Resolution

Troubleshooting Alarm F on a Fanuc CNC servo amplifier requires a methodical approach, focusing on safety and detailed inspection. Following these steps, you can identify and resolve issues with the external cooling fan, ensuring your CNC machine returns to full operational status.

Contact T.I.E. Industrial today for assistance or to purchase high-quality refurbished Fanuc replacement parts. We provide expert support and a wide range of parts to keep your CNC operations running smoothly. Our dedicated team is here to help.

Was this helpful?

2 / 0