Robots and computer numerically controlled tools typically rely on multiple printed circuit boards to manage the whole machine, run subsystems and communicate with external devices. A Fanuc CNC machine relies on a variety of printed circuit boards to turn the code for an operation into actual work. Controllers, displays, servos, spindles, and operator control panels have boards that contribute to making them mill, cut, or turn as required. Yet these key electronic components might not be as well understood as they might be. Those PCBs are robust but not immune to wear and damage. So, it helps to know how your operating environment can affect their performance, what impending failure looks like, and how to get the temporarily disabled machine running again.

The 411 on Printed Circuit Boards in Fanuc CNC Machines

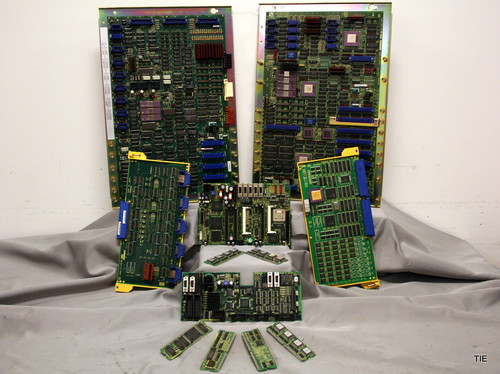

Unsurprisingly, if you open up various CNC machines you will find a wide variety of sizes and configurations in use. Those circuit boards transmit information to and from each subsystem in a Fanuc CNC lathe, for example.

These PCBS are fairly durable, lasting 15 to 20 years in use, and far longer when stored correctly. But these circuit boards can also fail prematurely due to the environment they operate in. Manufacturing errors can also create defects that cause a PCB to fail in use.

How Fanuc PCBs Go Bad

Aside from a hidden defect making a board fail, several things can go wrong with a PCB in your Fanuc CNC machine. The most obvious thing that could lead to failure is old age. A board that’s been used in a manufacturing environment for the past 14 or 15 years is realistically at or near the end of its life. Contacts, chips, and diodes inevitably begin to fail over time. Aside from aging, a PCB could go bad for several reasons:

- Exposure to moisture

- Dust accumulation

- Excessive vibration

- Impacts or physical shocks

- Exposure to high temperature

- Power surges

The circuit boards in a CNC machine are not fundamentally different from the boards in cash registers or laptops in terms of their resistance to those hazards. Therefore, they can begin to fail and potentially disable a piece of equipment.

Signs You May Need a New PCB

While encased in a display or controller, it can be impractical to inspect a PCB for signs of physical damage and wouldn’t be the best way to detect impending failure. The signs of damage may be subtle unless you can pull out the circuit board and inspect the various elements. Here are some visible signs of potential circuit board failure:

- Visible damage to chips and other components

- Burn marks

- Damaged wires

- Bent connectors or pins

- Scorching, cracking, or warping on any part of the board

Visual inspection is not the best approach though. Many circuit board issues are subtle. Instead, look for performance issues in the CNC machine. The most obvious place to look is the controller’s display, which may display an error code rooted in a PCB failure. Note that a bad wire or connection could be creating problems too.

So, error codes are one sign of trouble Other possibilities include:

- Data errors — Good data goes into the machine, but there are errors after that.

- No power — The machine has power but a component does not power up.

- Random rebooting — Something randomly restarts

- Alarm codes or lights — A certain numerical code on the device may indicate the circuit board is about to fail. LED lights may suggest a problem as well, for example, lights don’t come on that should be on.

Circuit board repair is rarely a DIY project, so if the board has failed, send it to a Fanuc parts dealer and buy a replacement.

Four Reasons to Consider Refurbished PCBS

The first and most important reason is probably budget. A professionally cleaned and reconditioned board can save you up to 75% off a new part. Secondly, older circuit boards, say from machines built in the late 1980s, may not be replaceable with new CNC parts because no one makes them. Thirdly, using refurbished parts in an older machine heads off the need to buy a new CNC machine. How much money does a mill or lathe cost in lost productivity while it is down? Finally, refurbished parts save energy and materials, so they are “greener” than new parts. PCB manufacturing is not the most environmentally friendly thing ever.

If a Fanuc PCB Goes Bad, Count on Us

Printed circuit boards are the invisible controllers of every CNC machine and application. As with drives, motors, and controls, the boards can fail or wear out, taking one of your mission-critical tools offline. You can minimize the cost of repairing the machine by purchasing a professionally refurbished PCB. Count on us to supply refurbished PCBS for your Fanuc CNC machine. We can service and support old and new Fanuc machines too.

Get your Fanuc CNC machine back up and running.

TIE offers same day shipping on more than 100,000 Fanuc CNC parts in stock. We offer a 1 year in service warranty on all parts and repairs.

Shop PartsWas this helpful?

0 / 0