Maximize the performance and lifespan of your CNC equipment with T.I.E. Industrial’s in-person CNC maintenance training. Our hands-on courses provide real-world experience, equipping technicians and operators with essential skills for maintaining and troubleshooting CNC machines. Whether you’re a beginner or an experienced professional, our expert-led training sessions will help you enhance operational efficiency, minimize downtime, and ensure your machines run at peak performance.

Why Hands-On CNC Maintenance Training Matters

Proper CNC machine maintenance is essential for minimizing unplanned downtime and ensuring precision in manufacturing operations. Without adequate training, minor issues can escalate into costly repairs, leading to production delays and equipment failures.

At T.I.E. Industrial, our in-person CNC maintenance training equips participants with practical skills to:

- Identify and troubleshoot common CNC failures before they impact production.

- Implement preventive maintenance strategies to extend machine lifespan.

- Fine-tune CNC machine settings and calibration for optimal performance.

- Diagnose Fanuc CNC system errors with expert guidance.

By attending our in-person CNC maintenance training, technicians gain real-world experience working with CNC equipment, ensuring they leave with the ability to apply their knowledge immediately in their workplace.

What to Expect from T.I.E. Industrial’s In-Person Training

Our hands-on training takes place in a fully equipped CNC lab, offering real-world application rather than just classroom theory. Here’s what makes T.I.E. Industrial’s training stand out:

Live Equipment Training & Real-World Scenarios

Unlike generic online courses, our in-person training allows participants to work directly on Fanuc CNC machines, troubleshooting live fault conditions and performing actual maintenance tasks under expert supervision.

Instructor-Led Small Group Training

Our classes maintain low student-to-instructor ratios, ensuring personalized instruction and hands-on guidance from experienced CNC technicians who have spent years in the field maintaining and repairing CNC systems.

Step-by-Step Machine Breakdown & Assembly

Participants will learn how to disassemble and reassemble CNC components, gaining a deep understanding of how each part functions and interacts within the system.

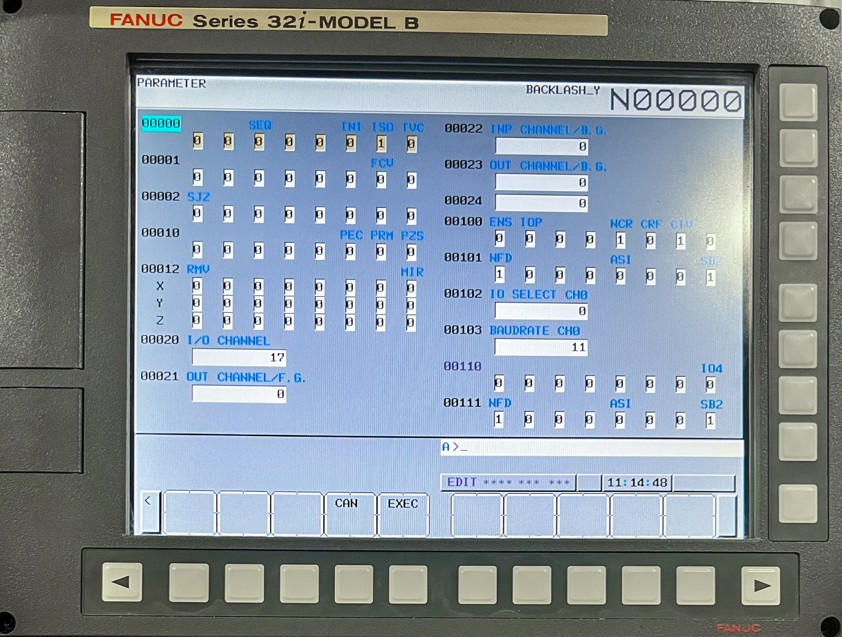

Advanced Troubleshooting & Error Code Analysis

Attendees will practice diagnosing Fanuc CNC error codes, learning how to interpret messages and resolve problems quickly to reduce downtime and prevent costly repairs.

T.I.E. provides Best-In-Class Fanuc CNC Maintenance Training

Our testing capabilities and extensive knowledge base make us the best choice for CNC maintenance training. Leveraging an intensive, proprietary curriculum developed by industry legend John Robbins, our training classes will enable you to grow your career, increase shop efficiency, and expand your horizons.

Whether you are new to CNC or a seasoned veteran, we have a class designed just for you.

All classes are intensive, 3-day sessions. The cost per student is $1,500 for Beginner and Intermediate classes and $1,800 for Advanced. A certificate is provided upon completion.

Basic Class

Best for students with no prior CNC experience. This class will cover an introduction to CNC machines. We will cover the environmental and mechanical components of the machine along with basic servo theory. In this class, you will:

- Disassemble and reassemble the simulator while looking at the major components and discussing how their failure will impact the machine.

- Review slideways, ballscrews, tool changers, lubrication systems and bearings.

- Review workings of the high voltage components such as motor contactors, relays, transformers and power supplies.

- Learn the proper procedure to check a motor and cable for shorts.

Basic Class Available Dates

- Feb. 4 – Feb. 6: Lafayette, Indiana

- March 4 – March 6: Lafayette, Indiana

- April 1 – April 3: Lafayette, Indiana

- April 29 – May 1: Lafayette, Indiana

- June 17 – June 19: Lafayette, Indiana

- July 15 – July 17: Lafayette, Indiana

- Aug. 5 – Aug. 7: Lafayette, Indiana

- Sept. 23 – Sept. 25: LaVergne, Tennessee

- Oct. 14 – Oct. 16: Lafayette, Indiana

- Dec. 2 – Dec. 4: Lafayette, Indiana

Request class registration for Basic CNC Troubleshooting – Fanuc Controls

Intermediate Class

Best for students with prior experience in the mechanical aspects of CNC. This class will cover the interface between the CNC, Ladder logic and machine tool. We will:

- Discuss how signals are sent from the machine side, processed in the ladder logic, and then sent to the CNC.

- Diagnostic screens that are used to troubleshoot the machine including the status screen, trace function, operator history, FSSB and alarm history.

- Troubleshoot a number of servo related alarms such as backlash compensation, grid shift and reference return procedures will be covered.

Intermediate Class Available Dates

- Feb. 18 – Feb. 20: Lafayette, Indiana

- April 8 – April 10: Shelby Township, Michigan

- May 6 – May 8: Lafayette, Indiana

- June 24 – June 26: Lafayette, Indiana

- July 22 – July 24: Lafayette, Indiana

- Aug. 19 – Aug. 21: Lafayette, Indiana

- Sept. 30 – Oct. 2: LaVergne, Tennessee

- December 16 – December 18: Lafayette, Indiana

Request class registration for Intermediate Fanuc Troubleshooting

Advanced Class

Best for students looking to go from “Pretty Good” to “Expert.” This class will build upon the information learned in the intermediate class. You will:

- Perform detailed inspections of the CNC to PMC addresses.

- Learn to troubleshoot issues such as an intermittent feed hold, axis interlock, M-code failures and others.

- Review CNC parameters and diagnostics.

- Demonstrate how to enable and disable scale feedback systems.

- Complete multiple labs using ladder logic function statements will provide the students with hands on troubleshooting techniques.

Advanced Class Available Dates

- March 11 – March 13: Lafayette, Indiana

- July 29 – July 31: Lafayette, Indiana

- Nov. 4 – Nov. 6: Shelby Township, Michigan

- Nov. 18 – Nov. 20: Lafayette, Indiana

Request class registration for Advanced Fanuc Troubleshooting

FAQs About CNC Maintenance Training

Who should enroll in T.I.E. Industrial’s CNC maintenance training?

This training is ideal for maintenance technicians, machine operators, engineers, and plant personnel responsible for CNC machine upkeep.

What is covered in the training?

Our courses cover preventive maintenance strategies, diagnostic techniques, error code troubleshooting, machine calibration, Fanuc system maintenance, and hands-on repair exercises.

How long does the in-person training last?

Each CNC maintenance training course is a three-day immersive program, balancing classroom instruction with practical machine application.

Do I need prior CNC experience?

No prior experience is required. We offer courses tailored for beginners, intermediate technicians, and advanced professionals.

Will I receive certification upon completion?

Yes, all participants receive an official certificate of completion, validating their expertise in CNC maintenance and troubleshooting.

Take Control of Your CNC Maintenance – Sign Up Today

Maximize your CNC machine performance and reduce downtime with expert-led in-person CNC maintenance training from T.I.E. Industrial. Our hands-on approach ensures you leave with practical skills you can apply immediately. Sign up for a class today.

To request information on a class, email partsales@tieindustrial.com