In the intricate world of manufacturing, precision and reliability are paramount. The heart of many manufacturing processes beats with the help of Fanuc equipment. But what do those cryptic Fanuc part numbers really mean? For maintenance managers and technicians tasked with keeping the production line running smoothly, understanding Fanuc part numbers is essential.

Fanuc, a global leader in CNC and automation technology, uses a specific coding system for its parts. These codes contain vital information about the components, and deciphering them can make your maintenance tasks much more efficient. In this blog post, we’ll break down Fanuc part numbers, shedding light on the mystery behind those alphanumeric combinations.

Cracking the Fanuc Code

Fanuc part numbers consist of a series of letters and numbers that provide key information about the part. Let’s dissect a typical Fanuc part number to understand its components:

- A02B-0###-B###: Fanuc Control Systems & Complete CNC.

Here’s how to interpret the Fanuc part number above:

- A02B: The first segment typically represents the product family or category. In this case, it’s a Fanuc Control System or Complete CNC.

- 0###: The second part, where ‘#’ represents a variable digit, provides details about the series or version of the product.

- B###: The last part often signifies variations or subcategories within the product family.

Now, let’s explore some common Fanuc part numbers and their meanings:

1. Fanuc Control Systems & Complete CNC (A02B-0###-B###)

This code encompasses the core of Fanuc’s CNC technology, which is the brains behind many manufacturing operations.

2. Fanuc MDI Unit (A02B-0###-C###)

MDI units, CRTs, LCDs, and operator panels fall under this category, essential for interfacing with CNC systems.

3. Fanuc I/O Modules (A03B-08##-C###)

I/O modules, both full-sized and half-sized, are crucial for connecting various devices to the CNC system.

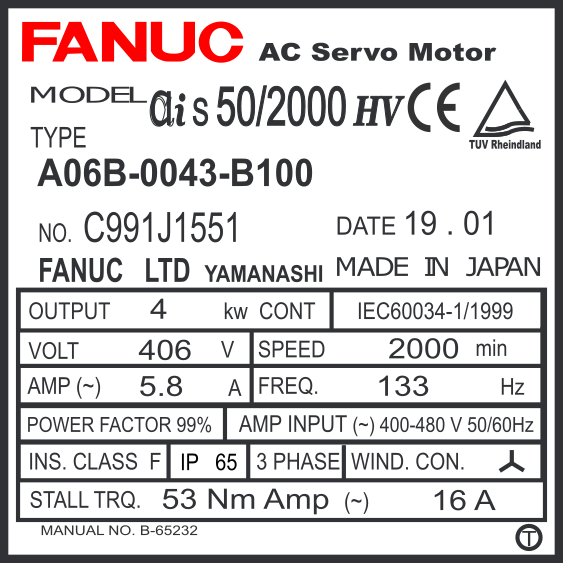

4. Fanuc Motors (A06B-####-B###)

Fanuc motors drive the machinery, and their part numbers help identify different motor types and specifications.

5. Fanuc Drives (A06B-6###-H###)

Drives are responsible for controlling motor movements, and their part numbers indicate specific drive models.

6. Fanuc Alpha Modules (A06B-6070-H### onwards)

Alpha modules include SVM, SVU, PSM, SPM, and more, which are integral to CNC systems.

7. Fanuc Tapereaders (A13B-0###-####)

These part numbers correspond to various tapereader models used for data input.

8. Fanuc Power Supply Units (A14B-####-####)

These units provide power to the CNC system, and part numbers help identify different types and capacities.

9. Fanuc Control and Drive Boards (A16B-####-####)

These boards are essential components of Fanuc CNC systems, and their part numbers distinguish between different types and versions.

10. Fanuc PCBs (A20B-####-####)

Part numbers for PCBs (Printed Circuit Boards) specify their use in drive, system, or power supply applications.

11. Fanuc Transistor Modules (A50L-0001-0###)

Transistor modules play a role in power regulation within the CNC system.

12. Fanuc Monitors (A61L-0001-00##)

These are display units used for monitoring and control purposes.

13. Fanuc Connectors and Sockets (A63L-0001-0###)

Part numbers for connectors and sockets help maintenance teams identify and source the right components.

14. Fanuc Transformers (A80L-0001-0###)

Transformers are critical for voltage conversion within the CNC system.

15. Fanuc Keyboards and Soft-keys (A86L-0001-0###)

Part numbers for keyboards and soft-keys enable efficient maintenance and replacement.

16. Fanuc Memory (A87L-0001-0###)

Memory modules are essential for storing and processing CNC programs and data.

17. Fanuc Membranes (A98L-0001-0### and A98L-0005-0###)

Different types of membranes are used in various parts of Fanuc equipment.

18. Fanuc Batteries (A98L-0001-09## and A98L-0031-0###)

Batteries are essential for retaining important data and settings in the CNC system.

19. Fanuc Encoders (A860-0###-T###)

Encoders are critical for precise positioning and feedback in CNC machinery.

20. Fanuc PCB Fabrication (A350-####-####)

These codes pertain to PCB fabrication processes used by Fanuc.

21. Fanuc Tapereaders (A860-0###-T###)

Tapereaders are used for data input, and their part numbers help identify specific models.

22. Fanuc Keyboards (N860-####-####)

Part numbers for keyboards used in Fanuc systems are represented in this category.

Still Confused? At T.I.E. We’re Here to Help!

Understanding Fanuc part numbers can be challenging, but it’s crucial for efficient maintenance and replacement. If anything in this guide is unclear or if you have specific questions about Fanuc parts, don’t hesitate to reach out to us. Our experts are here to provide clarification and assistance.

Explore More Resources With our Online Tech Support Library

For additional insights and information related to Fanuc equipment and maintenance, visit our Fanuc Alarm Codes page. We’ve got a wealth of resources to help you keep your manufacturing facility running smoothly.

Decoding Fanuc part numbers is a valuable skill for maintenance managers in manufacturing facilities. These codes contain vital information about Fanuc components, allowing for quicker identification, sourcing, and replacement of parts. With this knowledge in hand, you can ensure the continued efficiency and productivity of your manufacturing operations.

Was this helpful?

6 / 0