Have you ever heard someone say, “There’s no manual for that?” It can be frustrating when you are unsure where to turn when problems arise, especially with complex manufacturing equipment like CNC machine systems. Fanuc, a leader in manufacturing automation, provides a range of comprehensive manuals to support users of their CNC machines and robotic systems. These manuals are essential for ensuring Fanuc equipment’s proper setup, operation, and maintenance. This guide will delve into the types of manuals available, their uses, and how they can help you maximize the efficiency and longevity of your CNC machines and robotic systems.

Why Fanuc Manuals Are Essential

Fanuc manuals are indispensable for anyone working with CNC machines and robotic systems. They provide detailed information on various aspects of Fanuc equipment, ensuring that users can operate their machinery safely and effectively. Here’s a closer look at some of the primary types of manuals and their purposes.

Types of Fanuc Manuals

1. Connection Manuals

- B-64302EN Connection Manual (Hardware)

- B-64303EN Connection Manual (Function)

Connection manuals are vital for setting up your Fanuc CNC machines. These guides provide detailed instructions on wiring and configuring your equipment, ensuring all components are correctly connected and communicating. The hardware manual (B-64302EN) covers the physical connections, including pin layouts, cable specifications, and grounding methods. The function manual (B-64303EN) focuses on configuring the machine’s software settings to ensure proper communication between different system parts, such as PLCs, HMIs, and servo drives.

2. Operator’s Manuals

- B-64303EN-1 Operator’s Manual (For Lathe System)

- B-64304EN-1 Operator’s Manual (For Machining Center System)

Operator’s manuals are designed to help users understand the controls and functions of their CNC machines. These manuals cover everything from basic operations to advanced functions, enabling operators to use their machines efficiently and effectively. For example, the lathe system manual (B-64303EN-1) includes detailed instructions on setting up workpieces, selecting appropriate tooling, and programming the machine for various lathe operations. The machining center system manual (B-64304EN-1) provides similar guidance for milling, drilling, and tapping tasks.

3. Maintenance Manuals

- B-64304EN-2 Maintenance Manual

- B-65282EN Fanuc AC Spindle Motor ai Series Maintenance Manual

Maintenance manuals are crucial for keeping your CNC machines in top condition. They provide comprehensive guidelines on routine maintenance tasks, troubleshooting common issues, and performing necessary repairs. The general maintenance manual (B-64304EN-2) includes instructions on lubrication schedules, cleaning procedures, and periodic inspections. The specific maintenance manual for the Fanuc AC spindle motor ai series (B-65282EN) offers detailed guidance on maintaining these critical components, such as checking for bearing wear, ensuring proper alignment, and calibrating spindle speeds.

4. Parameter Manuals

- B-64305EN Parameter Manual

- B-65285EN Fanuc AC Servo Motor ai Parameter Manual

Parameter manuals are essential for configuring Fanuc CNC machines to meet specific operational requirements. These guides detail various parameters that can be adjusted to optimize machine performance and efficiency. The general parameter manual (B-64305EN) covers multiple settings, including feed rates, acceleration/deceleration times, and tool offsets. The parameter manual for the Fanuc AC servo motor ai series (B-65285EN) provides in-depth information on adjusting servo parameters, such as gain settings, response times, and positional accuracy, to ensure smooth and precise movements.

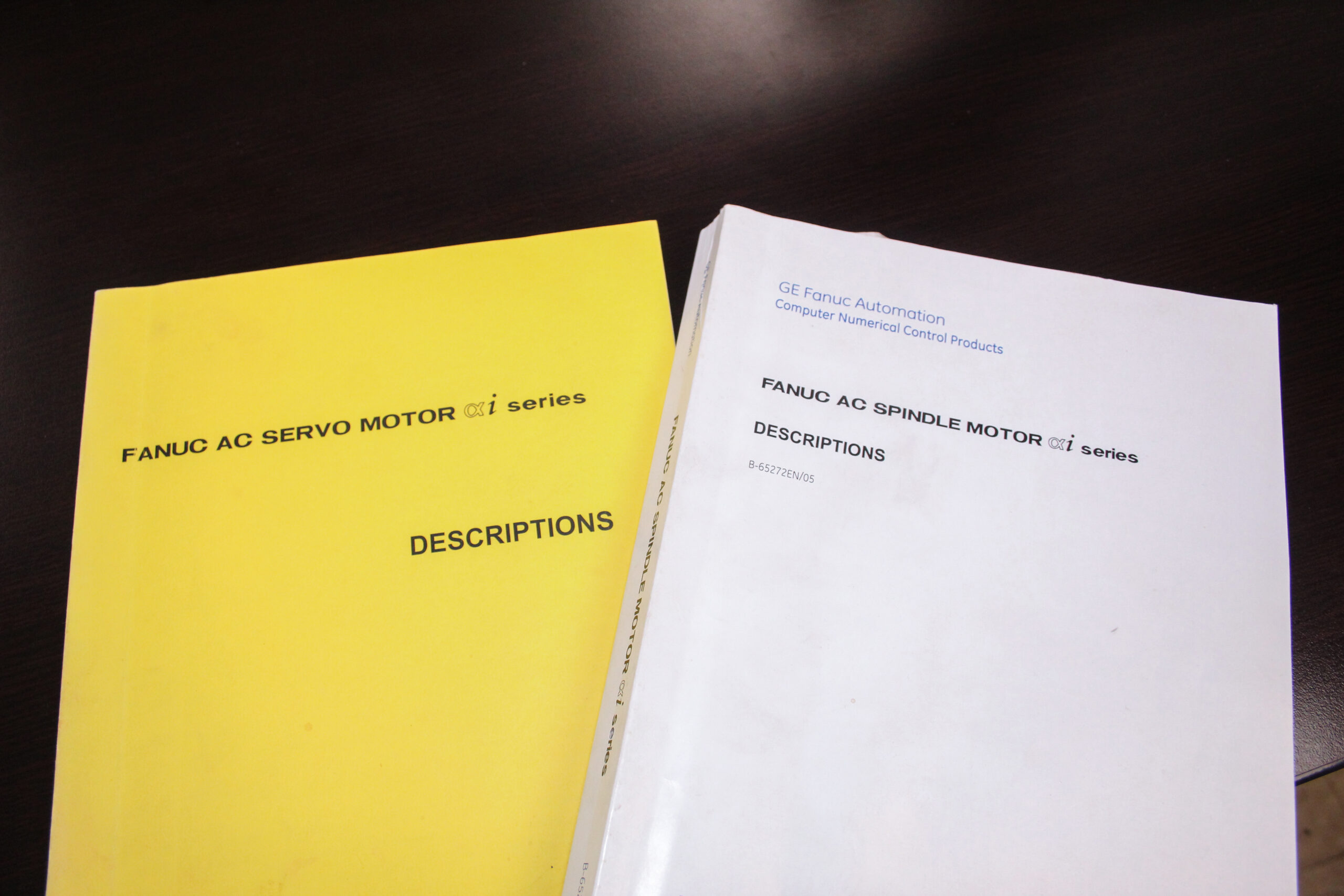

5. Motor and Amplifier Manuals

- B-64310EN Fanuc AC Servo Motor ai Series Descriptions

- B-65262EN Fanuc AC Spindle Motor ai Series Descriptions

- B-65272EN Fanuc Servo Amplifier ai Series Descriptions

- B-65270EN Fanuc AC Spindle Motor ai Series

These manuals provide detailed descriptions and specifications for Fanuc motors and amplifiers. They are essential for understanding the capabilities and limitations of your machine’s components, ensuring you can select the right parts for your needs. For instance, the AC servo motor ai series description manual (B-64310EN) includes information on torque curves, speed ranges, and power requirements. The AC spindle motor ai series description manual (B-65262EN) provides similar data for spindle motors, which are crucial for high-speed machining operations. The servo amplifier description manual (B-65272EN) explains the various models available, their features, and how to integrate them into your CNC system.

Benefits of Using Fanuc Manuals

Using Fanuc manuals offers several benefits that can significantly enhance your CNC machining operations:

- Enhanced Safety By following the guidelines provided in Fanuc manuals, you can ensure that your equipment is set up and operated safely, minimizing the risk of accidents and injuries.

- Improved Efficiency Proper use of Fanuc manuals can help you understand your machine’s capabilities and how to optimize them, leading to more efficient operations and higher productivity.

- Reduced Downtime Regular maintenance, as outlined in the manuals, can prevent unexpected breakdowns and reduce downtime, keeping your production lines running smoothly.

- Cost Savings By performing maintenance and troubleshooting tasks in-house, you can save on costly service calls and repairs.

How to Access Fanuc Manuals

- Fanuc’s Official Website: The official Fanuc website offers a comprehensive library of manuals for different models and components.

- Authorized Distributors: Authorized Fanuc distributors and suppliers, like T.I.E. Industrial, often provide manuals with purchased equipment or upon request.

- Online Communities: Various online forums and communities dedicated to CNC machining and Fanuc equipment may also offer access to manuals and other helpful resources.

There IS a manual for That!

Fanuc manuals are invaluable resources for anyone using CNC machines and robotic systems. By providing detailed instructions on setup, operation, and maintenance, these manuals help ensure that your equipment operates safely, efficiently, and reliably. Whether you are a seasoned operator or new to CNC machining, using Fanuc manuals will undoubtedly enhance your ability to maintain and operate your machinery effectively.

For more information or to access specific Fanuc manuals, contact T.I.E Industrial today. Investing time in understanding and utilizing these manuals will pay off in the long run, keeping your machines running at peak performance and extending their operational lifespan.

Was this helpful?

1 / 0