Hearing the sound of any alarm can bring almost instant dread. The high-pitched tone of a smoke alarm or the wail of a fire truck- all elicit their own sense of worry. Alarms also occur in the industrial world, typically meaning that some issues have arisen in the robotic systems used in manufacturing.

Operating Fanuc robots accurately is crucial in any manufacturing process that uses them, no matter the task. One common issue operators often face is dealing with run request failures and repeatedly using the FCTN (Function) Abort All command. This guide will show you how to set up and use user alarms to simplify this process, making your work smoother and more efficient. We’ll cover setting up user alarms in Fanuc robotic systems, understanding their functions, and how they can improve your programming experience.

Knowing how to use the User Alarm screen allows you to define a message that will be displayed on the teach pendant status line. This message is displayed when a user alarm instruction is executed in a teach pendant program.

Understanding the Problem: Run Request Failures

Imagine you’re running a job on your Fanuc robot and accidentally pick the wrong one. You hit start and forward, but the run request fails. Typically, you’d need to use the FCTN Abort All command, hit reset, and go through several steps to fix this. However, you can simplify this process with user alarms with a single button press.

Setting Up User Alarms

User alarms in Fanuc robots can help safeguard your programs and automate specific responses to events. Here’s a step-by-step guide to setting them up:

Note: By default, the severity of a user alarm is STOP, which pauses the program and stops robot motion. If you want to change the severity of the user alarm, you must set the appropriate $UALRM_SEV[n] system variable to a value that corresponds to the severity you want. “n” corresponds to the number of the user alarm

Step 1: Accessing Variables

- Navigate to System: On your teach pendant, go to the system menu.

- Select Variables: Enter the variables section to set up your user alarms.

Steps

1. Press MENU.

2. Select SYSTEM.

3. Press F1, [TYPE].

4. Select Variables. You will see a screen similar to the following

5. Move the cursor to $UALRM_SEV and press ENTER.

Step 2: Configuring User Alarms

- Find the UALRM Variables: Look for the UALRM message and UALRM severity in the variables list. Move the cursor to $UALRM_SEV and press ENTER.

- Set the Alarm Message: Click on the 10-string list for UALRM_message and input your desired message. For example, you could set a message like “Abort All.”

- Set the Severity: Adjust the severity in UALRM severity to determine the alarm’s impact. Type the number that corresponds to the severity you want and press ENTER. The severity levels range from 0 (no action) to combinations that pause, stop, or abort programs and motion.

Severity Levels and Their Effects

- 0: No action.

- 2: Pauses the program.

- 3: Aborts with an error.

- 4: Stops any program motion.

- 6: Pauses the program and stops motion.

- 8: Cancels program motion.

- 10: Pauses the program and cancels motion.

- 11: Aborts the program and cancels motion.

- Adding 16: Turns off all servos.

- Adding 32: Applies action to all programs and motions.

- Adding 64: Requires a cold start to reset the controller.

Implementing User Alarms in Your Program

You need to integrate user alarms into your robotic programming to use them effectively. Here’s how:

Creating a Macro for User Alarms

- Create a New Job: Go to the job creation menu and select “Create.”

- Set Job Details: Change the group mask to a star (*) to ensure it’s a non-motion job. This setup allows you to call the macro without affecting motion.

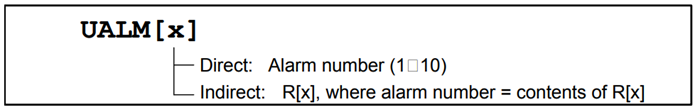

- Add the Alarm Instruction: In the job, go to instruction > miscellaneous > UALM[x]. Select the user alarm number you set up.

For example: INTP 213 UALM[1] Check feeder (RSR001, 47)

Running the User Alarm

- Run the Macro: Execute the job with the user alarm command to see it in action. For example, if you programmed UALARM number 1, running the job should trigger the user alarm as configured.

- Assign to User Key: Go to setup > macros and assign your new job to a user key for easy access. This lets you trigger the user alarm with a single button press.

Note: If the program is resumed, program execution will continue from the next program line. The user alarm instruction specifies the alarm message to be displayed. Refer to the “General Setup” chapter of the Setup and Operations Manual for information on how to define the contents of a user alarm.

Practical Applications

Example: Abort All Programs and Cancel Motion

- Combine Severity Levels: Combine the severity levels to abort all programs and cancel all motion. For instance, using a severity of 11 aborts the program and cancels motion.

- Set the User Alarm: Configure the user alarm with severity 11 and assign it to a job.

- Trigger the Alarm: Use the assigned user key to trigger the alarm whenever necessary.

Example: Warning Messages

- Set a Warning: Configure a user alarm with a severity of 0 for non-critical warnings.

- Display the Message: Set the UALRM message to something like “Check Settings” to alert operators without stopping the program.

- Run the Job: Use the job with the user alarm to display the warning message when specific conditions are met.

User Alarms Help Avoid User Error and Optimize Operations

Mastering user alarms in Fanuc robotic programming can streamline your workflow, enhance safety, and improve overall efficiency. Whether you are dealing with run request failures or need automated responses to specific events, user alarms offer a powerful tool to enhance your robotic operations.

For more information on Fanuc robots’ user alarms, troubleshooting tips, and detailed guides, contact the experts at T.I.E. Industrial today. In addition to our extensive inventory of refurbished Fanuc replacement parts, our technicians can help guide you in making the right choices to keep your robots running at peak performance.

By implementing the strategies outlined in this guide and relying on the parts, knowledge, and support from T.I.E Industrial, you’ll be well-equipped to handle any challenges that come your way, making your work with Fanuc robots more effective and hassle-free.

Was this helpful?

0 / 0