Heat, cold, humidity, dust—robot grease has to handle more than moving parts. And if the grease can’t hold up, neither can your industrial robots. That’s the kind of headache no one needs on a tight production schedule. Whether you’re maintaining a Fanuc arm in a cleanroom or a CNC setup in a sweltering machine bay, grease performance ties directly to uptime.

Not all greases react the same once the temperature swings or the air quality shifts. Understanding how the environment affects grease is how you keep your equipment moving without surprises. This article will explore the best robot grease for high heat and low temperatures.

In This Article

- Why Environment Affects Grease Performance

- Cold Starts and Low Temps: How Viscosity Becomes the Enemy

- Dirty Air and Moisture in the Environment

- Keep Your Robots Running Smoothly

- How Temperature Affects Robot Grease Performance

- Find the Robot Grease You Need at T.I.E. Industrial

- Choosing the Best Grease for the Job

- Frequently Asked Questions About Robot Grease

Why Environment Affects Grease Performance

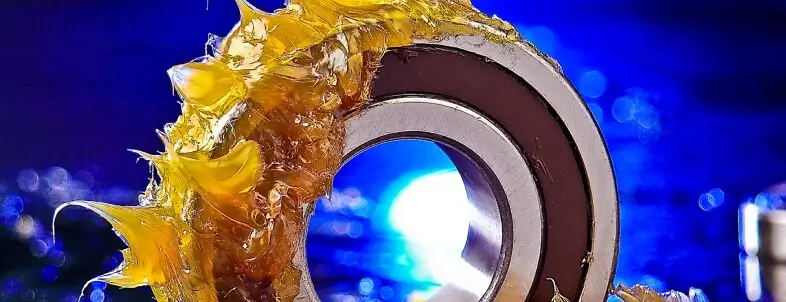

Grease keeps your robot parts moving, but it’s not a set-it-and-forget-it part of the system. The surrounding environment plays a bigger role than most people realize, especially when cycles are tight and downtime is expensive. Extreme temps, moisture, dust, and even airflow patterns can quietly wreck how grease behaves.

One of the main things to watch is grease viscosity, the thickness of the grease and how easily it moves through the robot’s joints and gearboxes. The wrong viscosity—too thick in the cold or too thin in the heat—can cause drag, wear, or flat-out failure. That directly impacts grease performance and, more importantly, how long your robot stays functional without needing intervention.

So, if you’re troubleshooting repeat issues or setting up robots in a new environment, skip the generic advice. Start by looking at how the environment and robot grease interact and work from there.

Cold Starts and Low Temps: How Viscosity Becomes the Enemy

Low temperatures mess with grease in a way that shows up fast—especially during startups. As the temperature drops, grease viscosity increases. What was once smooth and consistent turns thick and sluggish. That resistance gets passed straight to the robot’s joints, making axes respond slowly or lock up entirely.

If you work in cold warehouses or outdoor setups, expect issues like jerky motion, slow calibration, or failed homing routines. It’s not a mechanical fault—it’s the grease not moving the way it should.

This is where the best robot grease for low temperatures earns its keep. Nabtesco’s RV Grease LB00, for example, stays mobile in the coldest conditions. It holds its structure and delivers consistent grease performance, even when the shop floor feels like a walk-in freezer. Don’t wait for cold-weather failures to make the case – use the right grease before things seize up.

Dirty Air and Moisture in the Environment

Not every robot runs in a climate-controlled box. Many operate in cutting fluid mist, welding smoke, dust, or humid air. All of that hits the grease first. Over time, moisture and airborne grit work their way into seals and joints, leading to faster grease degradation. Once that starts, you’ll see increased wear, unexpected friction, and grease that looks more like sludge than lubricant.

Poor air quality compromises grease performance from the inside out. Even the best product will break down early if it’s constantly absorbing water or getting contaminated by fine debris.

In setups where you can’t clean up the environment, grease maintenance has to be more aggressive. Use OEM-approved grease that can handle some exposure, check seals regularly, and don’t let inspection intervals slide. Managing the environment and robot grease together is the only way to keep things running clean.

Keep Your Robots Running Smoothly

Choosing the right grease can prevent costly downtime and maintenance headaches. Make sure you order from T.I.E. Industrial for lubricants that maintain optimal performance.

- Works with numerous robot models

- Available for immediate shipment—no delays

- Supported by knowledgeable experts to help you find the right fit

How Temperature Affects Robot Grease Performance

High heat can quickly break down industrial robot grease, leading to serious performance issues. As temperatures rise, grease thins out and loses its viscosity and ability to maintain a proper lubricating film. You end up with excessive wear on gears and joints, leading to increased friction, overheating, and, eventually, mechanical failure.

The grease can also separate or degrade, leaving behind residues that clog parts and interfere with smooth movement. In extreme heat environments, choosing the right grease becomes critical for maintaining optimal robot performance and longevity.

If you’re looking for the best robot grease for high heat, Nabtesco’s Vigo Grease RE0 is an excellent choice. It maintains its structure across a wide temperature range and provides superior lubrication, even under sustained temperatures. This high-quality grease ensures smooth operation, reduces wear, and helps prevent costly downtime in high-temperature settings.

Find the Robot Grease You Need at T.I.E. Industrial

Choosing the Best Grease for the Job

Selecting the right grease is not a one-size-fits-all situation. The key is matching the grease to the specific environment your robot operates in. Temperature, humidity, and the presence of airborne contaminants all affect how well your grease performs over time.

Always check the OEM specifications to ensure the grease is suitable for your specific robot and conditions. While it might be tempting to choose a cheaper, generic option, skimping on quality can cost you more in the long run with increased maintenance and downtime.

For environments where extreme heat or cold is common, look for grease performance ratings that match those extremes. You can always rely on trusted brands from T.I.E. Industrial, which offers lubricants designed with your equipment’s longevity in mind.

Frequently Asked Questions About Robot Grease

The $5.8 billion global grease market can be confusing, but T.I.E. Industrial has the answers you need. Here are some common things people want to know.

Do different industries require different grease formulations?

Yes. Food-grade environments, high-speed aerospace manufacturing, welding bays, and cold storage all demand different formulations based on temperature, contamination risk, and operating load.

How can I adjust my maintenance schedule based on environmental conditions?

Shorten inspection and replacement intervals if your robots operate in excessive temperatures, humidity, or dusty air. Harsh conditions wear out grease faster, so you’ll need to stay ahead of breakdowns.

What are the signs that environmental conditions are degrading my robot’s grease?

Watch for unusual noise, increased resistance, visible residue, or sluggish motion. These symptoms usually point to grease degradation caused by heat, moisture, or contamination.

Was this helpful?

0 / 0