In industrial settings, the longevity of your equipment is an essential feature of one of your most significant business investments. If vital machinery continuously breaks down or wears out, your bottom line can take a significant hit. Therefore, regular assessments and maintenance are recommended to be integrated into operations.

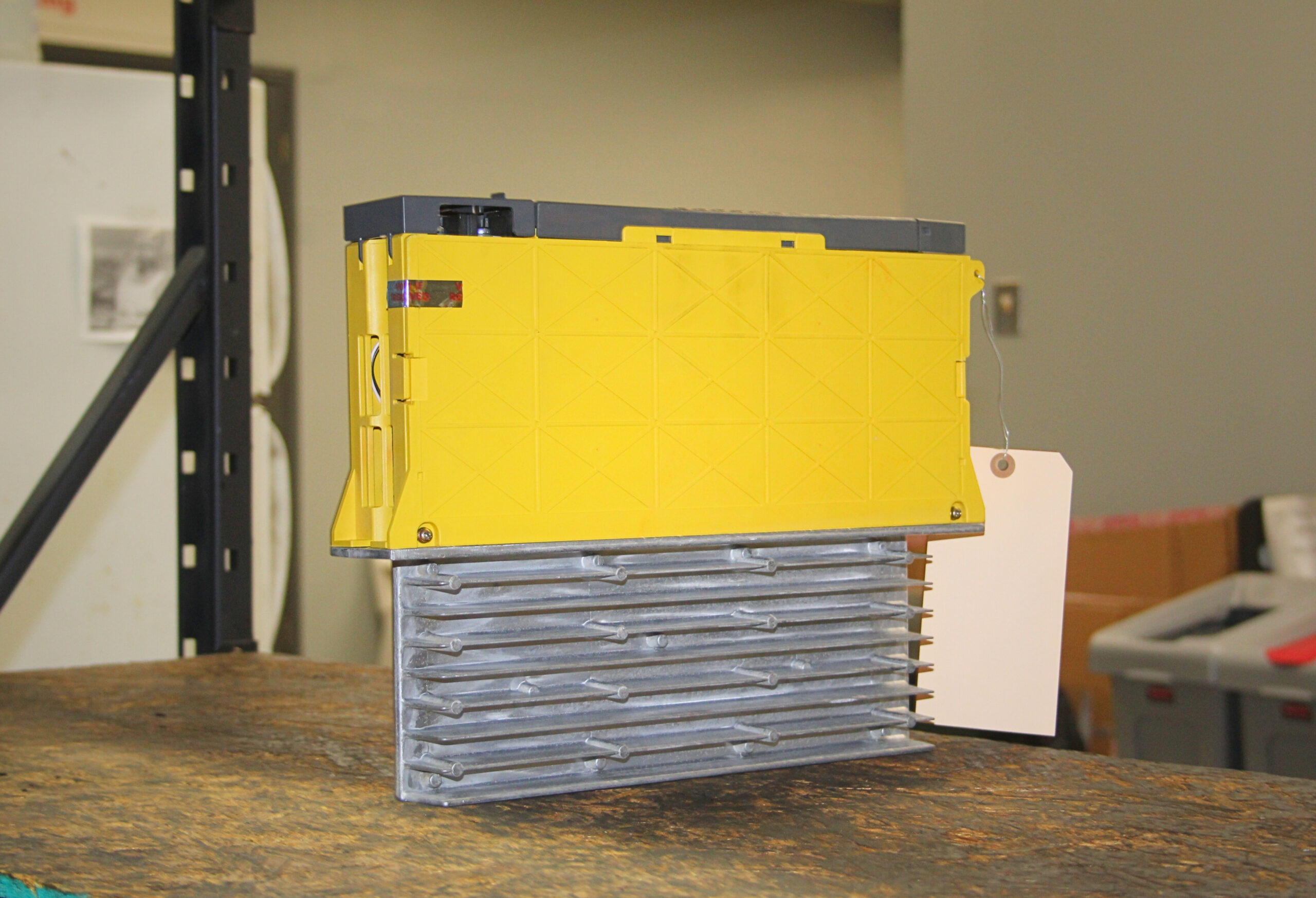

Critical components to focus on regarding CNC machine maintenance are your Fanuc amps, which are responsible for amplifying control signals and powering the motors. Proper maintenance of these amps is crucial for ensuring the overall functionality and longevity of your CNC machine. This article will provide insight into your amps and some maintenance tips to help you prolong their life, ensuring optimal performance and efficiency.

Decoding the Dynamo: The Heartbeat of Your CNC Machine- the Amp

Fanuc amps, short for amplifiers, play a crucial role in the operation of CNC (Computer Numerical Control) machines by amplifying the signals and providing the necessary motor power. These amplifiers are a vital component of the overall CNC system, contributing to the precision, efficiency, and reliability of the machine. Here are the key functions and roles of Fanuc amps:

Simple Amplification. Fanuc amps are responsible for amplifying the control signals generated by the CNC controller. These signals determine the desired movements and positions of the various machine components, such as the spindle and axis motors.

Power Supply to Motors. The primary function of Fanuc amps is to supply power to the motors within the CNC machine. This power is essential for driving the movements of the machine, including the rotation of the spindle and the linear motion of the axes.

Controlled Motor Movements. Fanuc amps ensure that the motors receive the appropriate power to execute precise and controlled movements. This is crucial for achieving accuracy in machining processes, such as milling, turning, and drilling.

Energy Efficiency. Well-designed Fanuc amps contribute to energy efficiency by optimizing power usage during different machining operations. This not only helps reduce energy consumption but also minimizes heat generation, contributing to the overall longevity of the equipment.

Feedback Systems Integration. Fanuc amps often work in conjunction with feedback systems, such as encoders and sensors, to provide accurate position feedback. This integration ensures that the CNC machine can continuously adjust and correct its position during operation, leading to improved precision.

Dynamic Response Control. Fanuc amps are designed to have a high dynamic response, allowing them to respond quickly to changes in control signals. This responsiveness is essential for achieving rapid and accurate movements, especially in high-speed machining applications.

Fault Detection and Protection. Fanuc amps are equipped with built-in fault detection mechanisms. In the event of abnormalities or faults, such as overcurrent or overheating, the amps can trigger protective measures to prevent damage to the motors and other components.

Compatibility with Control Software. Fanuc amps must be compatible with the control software used in the CNC machine. This compatibility ensures seamless communication between the CNC controller and the amplifiers, allowing for precise machine control.

Overall, Fanuc amps are critical components that enable CNC machines to translate digital control signals into physical movements with a high degree of accuracy and efficiency. Their proper maintenance and functioning are essential for the optimal performance and longevity of CNC machining systems.

Best Practices for CNC Machine Amp Maintenance

Regular Inspection and Cleaning

- Conduct routine visual inspections to identify any signs of wear, damage, or loose connections.

- Keep the amps and surrounding areas clean from dust and debris affecting cooling systems.

Temperature and Environmental Control

- Ensure that the operating temperature of the amps is within the recommended range.

- Implement environmental controls to protect amps from extreme conditions, such as humidity or temperature fluctuations.

Monitor Power Supply

- Regularly check the power supply for fluctuations or irregularities that may impact the performance of Fanuc amps.

- Utilize voltage regulation devices to maintain a stable power source.

Software Updates and Compatibility

- Keep the control software and firmware of the CNC machine up-to-date to ensure compatibility with Fanuc amps.

- Follow manufacturer guidelines for software updates and compatibility checks. Top of Form

Lubrication of Moving Parts

- If applicable, lubricate moving parts associated with the amps to reduce friction and wear.

- Use recommended lubricants and follow the manufacturer’s lubrication schedule.

Timely Repairs and Replacement

- Address any identified issues promptly through repairs or, if necessary, replacement of damaged or faulty Fanuc amps.

- Consider utilizing high-quality refurbished or replacement parts from T.I.E. Industrial.

Examples of Fanuc Amp Models and Manufacturing Purposes

Are you familiar with the Fanuc amps used in your manufacturing facility? Below are some specific model numbers of Fanuc amps and the manufacturing purposes for which they are commonly used:

Fanuc A06B-6096-H207 is widely used in CNC machining centers for precise control of Fanuc spindle motors.

Fanuc A06B-6110-H026 is commonly found in CNC lathes, providing reliable power for controlling cutting and turning operations.

Fanuc A06b-6132-H002 is applied in CNC milling machines to ensure accurate and controlled movements of the milling tool.

These Fanuc amp model numbers are just a few examples of the diverse range of applications within the manufacturing industry. The amps are tailored to specific tasks, contributing to the efficiency and precision of various CNC machines.

At T.I.E. Industrial, we understand the importance of Fanuc amps in the seamless operation of CNC machines. By following these maintenance tips and utilizing our high-quality Fanuc refurbished and replacement parts, you can significantly prolong the life of your amps, ensuring uninterrupted production and minimizing downtime. Trust T.I.E. Industrial for all your CNC machine needs, where quality and durability go hand in hand.

Was this helpful?

1 / 0