The manufacturing industry is constantly evolving, and with it comes a growing demand for skilled CNC machine operators. Let’s look in-depth at what is included in a CNC machining career.

Why Choose CNC Machining?

CNC (Computer Numerical Control) machining involves using computers to control machine tools, resulting in precise and efficient production processes. Learning CNC machining opens up numerous career opportunities, offering stability, competitive wages, and the satisfaction of contributing to creating complex and essential products.

The Importance of Skilled CNC Operators

There is a notable shortage of skilled operators in the current job market. Many experienced workers are retiring, leaving a gap that needs to be filled by well-trained professionals. Apprenticeship and training programs aim to develop the next generation of CNC machinists who can seamlessly integrate into the workforce.

What Do CNC Machine Apprentice and Training Programs Teach?

They are designed to equip individuals with the skills and knowledge necessary to operate and program CNC machines effectively. These programs combine theoretical education with hands-on training, ensuring apprentices are well-prepared for careers in numerous manufacturing industries.

1. Introduction to CNC Machining

- History and Evolution: Understanding the development of CNC technology and its impact on manufacturing.

- Basic Concepts: Learning the fundamental principles of CNC machining, including how CNC machines differ from traditional manual machines.

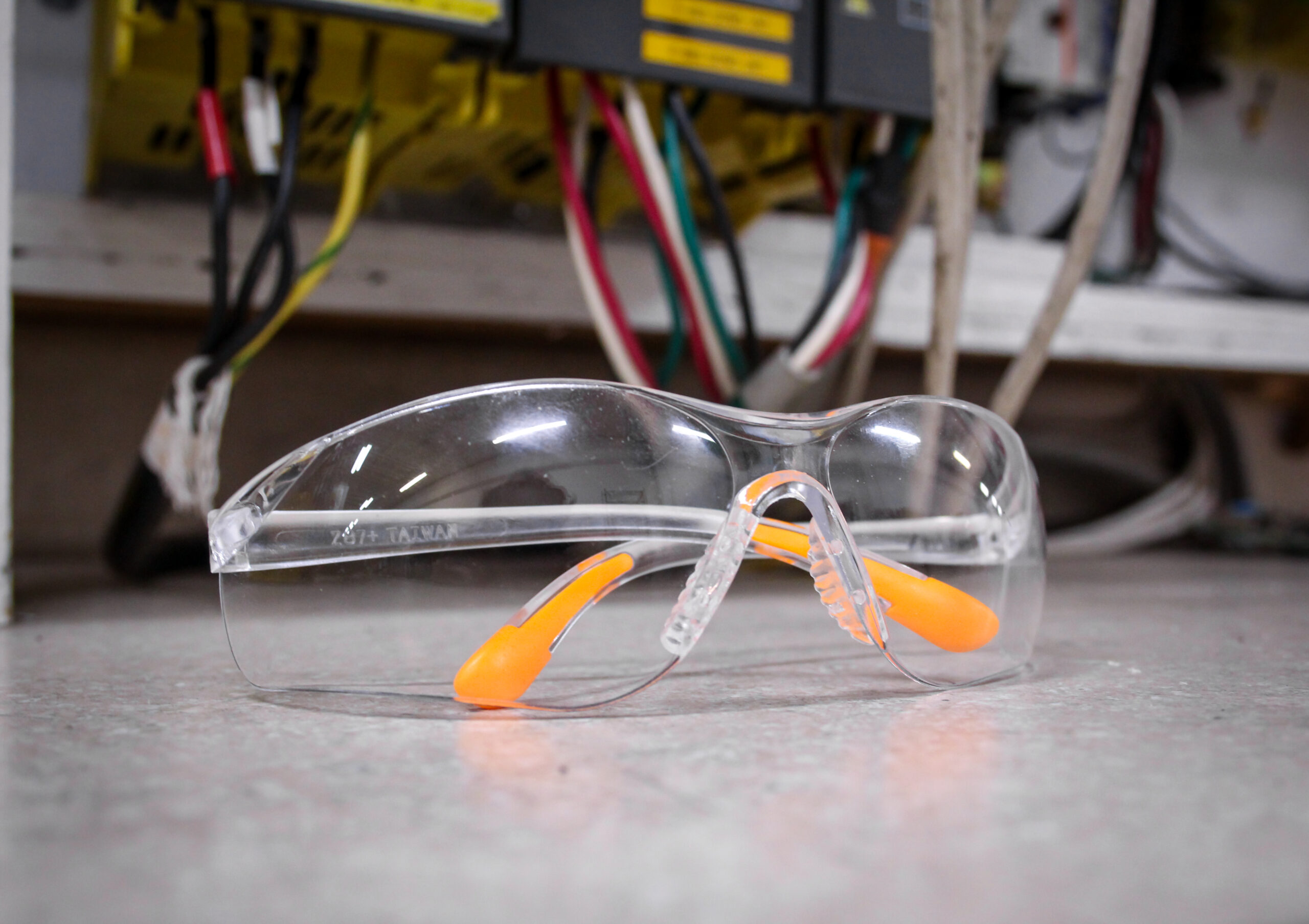

2. Safety Protocols

- Workplace Safety: Emphasizing the importance of safety in a manufacturing environment, including personal protective equipment (PPE) and safe handling of materials.

- Machine Safety: Specific safety procedures for operating CNC machines, such as emergency stop functions and safe maintenance practices.

3. Technical Drawing and Blueprint Reading

- Blueprint Reading: Interpreting technical drawings and blueprints to understand the specifications and requirements of the parts to be manufactured.

- Geometric Dimensioning and Tolerancing (GD&T): Learning the language of symbols and rules used in technical drawings to define the geometry of parts.

4. Mathematics for Machining

- Basic Math Skills: Refreshing fundamental math skills, including arithmetic, algebra, and geometry.

- Applied Mathematics: Calculating dimensions, tolerances, and other critical measurements specific to CNC machining.

5. CNC Programming

- G-Code and M-Code: Learning the programming languages used to control CNC machines. G-Code dictates movements and machining operations, while M-Code controls auxiliary functions.

- Manual Programming: Writing and understanding CNC programs manually.

- CAM Software: Using Computer-Aided Manufacturing (CAM) software to create and simulate CNC programs before execution.

6. Machine Operation and Setup

- Machine Components: Learning about the parts and functions of CNC machines, including spindles, tool changers, and control panels.

- Setup Procedures: Learning to set up CNC machines for different jobs, including installing and aligning tools, setting zero points, and loading materials.

- Operation Techniques: Operating CNC machines to perform various machining tasks, such as milling, turning, and drilling.

7. Tool Selection and Maintenance

- Tool Types and Uses: Identifying different types of cutting tools and their applications.

- Tool Maintenance: Maintaining and sharpening tools to ensure precision and longevity.

8. Material Properties and Selection

- Material Science: Understanding the properties of various materials, such as metals, plastics, and composites.

- Material Selection: Choosing appropriate materials for specific machining tasks based on their properties and the requirements of the finished product.

9. Quality Control and Inspection

- Inspection Techniques: Learning various methods of inspecting finished parts to ensure they meet specifications.

- Measurement Tools: Using calipers, micrometers, and coordinate measuring machines (CMM) to check dimensions and tolerances.

- Statistical Process Control (SPC): Applying statistical methods to monitor and control the machining process.

10. Advanced CNC Technologies

- Multi-Axis Machining: Understanding and operating multi-axis CNC machines for complex parts.

- Automation and Robotics: Integrating CNC machines with robotic systems for automated manufacturing processes.

- Additive Manufacturing: Exploring the basics of additive manufacturing (3D printing) and its integration with CNC technology.

11. Hands-On Training and Practical Experience

- Simulations: Using CNC simulators to practice programming and machining in a risk-free environment without the risk of damaging equipment.

- Real-World Projects: Working on actual machining projects to apply theoretical knowledge and gain practical experience.

- Troubleshooting and Problem-Solving: Diagnosing and fixing common issues that arise during CNC machining processes.

12. Soft Skills and Career Development

- Communication Skills: Enhancing verbal and written communication skills for effective collaboration in the workplace.

- Teamwork and Leadership: Developing the ability to work in teams and take on leadership roles.

- Job Readiness: Preparing resumes, practicing interview techniques, and understanding job market trends in the manufacturing industry.

Changing Perceptions of Manufacturing

One of the key goals of CNC machine apprenticeship and training programs is to change the outdated perception of manufacturing as a dark, dirty, and monotonous job. Many manufacturing environments are dynamic and engaging workplaces where operators have the chance to:

- Take on diverse tasks, from machine operation to programming.

- Explore their creativity and problem-solving skills.

- Contribute to the production of high-quality, complex parts.

CNC Machining: Where Technology and Science Meet Art in the Workplace

CNC machining is often compared to art as operators meticulously shape raw materials into precise components. This aspect of the job can be incredibly fulfilling, as it combines technical skills with creativity. Apprentices and trainees quickly realize that CNC machining is not just about pressing buttons but about making meaningful contributions to the manufacturing process.

Embarking on a career in CNC machining can be a rewarding and fulfilling choice, offering numerous opportunities for growth and development. Whether you are a high school student looking to start your career or someone seeking a new challenge, CNC machining with Fanuc training can be an exceptional career path. Explore the possibilities and take the first step toward a bright future in CNC machining today.

Was this helpful?

0 / 0