When working with high-tech manufacturing equipment like CNC machines, all technicians want their operations to go off without a hitch. Still, problems inevitably arise; therefore, it is essential to become familiar with alarm codes. One common issue faced by users of Fanuc CNC machine systems is the Alarm U or L on the Alpha I amplifier. This alarm indicates a loss of communication and can result in a system alarm, or “black screen of death,” where the control system immediately shuts down. This guide will walk you through troubleshooting these alarms and provide detailed steps to identify and resolve the problem before your production lines suffer downtime.

Understanding Fanuc Alarms U and L

Alarms U and L are specific to Fanuc CNC systems and relate to communication issues. These alarms are crucial because they halt operations, necessitating immediate attention to prevent prolonged downtime.

- Alarm U: This alarm signifies that the amplifier is not receiving communication from the next amplifier in the chain. Essentially, it indicates a breakdown in the upward communication flow.

- Alarm L: This alarm means the amplifier is not sending communication down the chain. It indicates an issue with the downward communication flow.

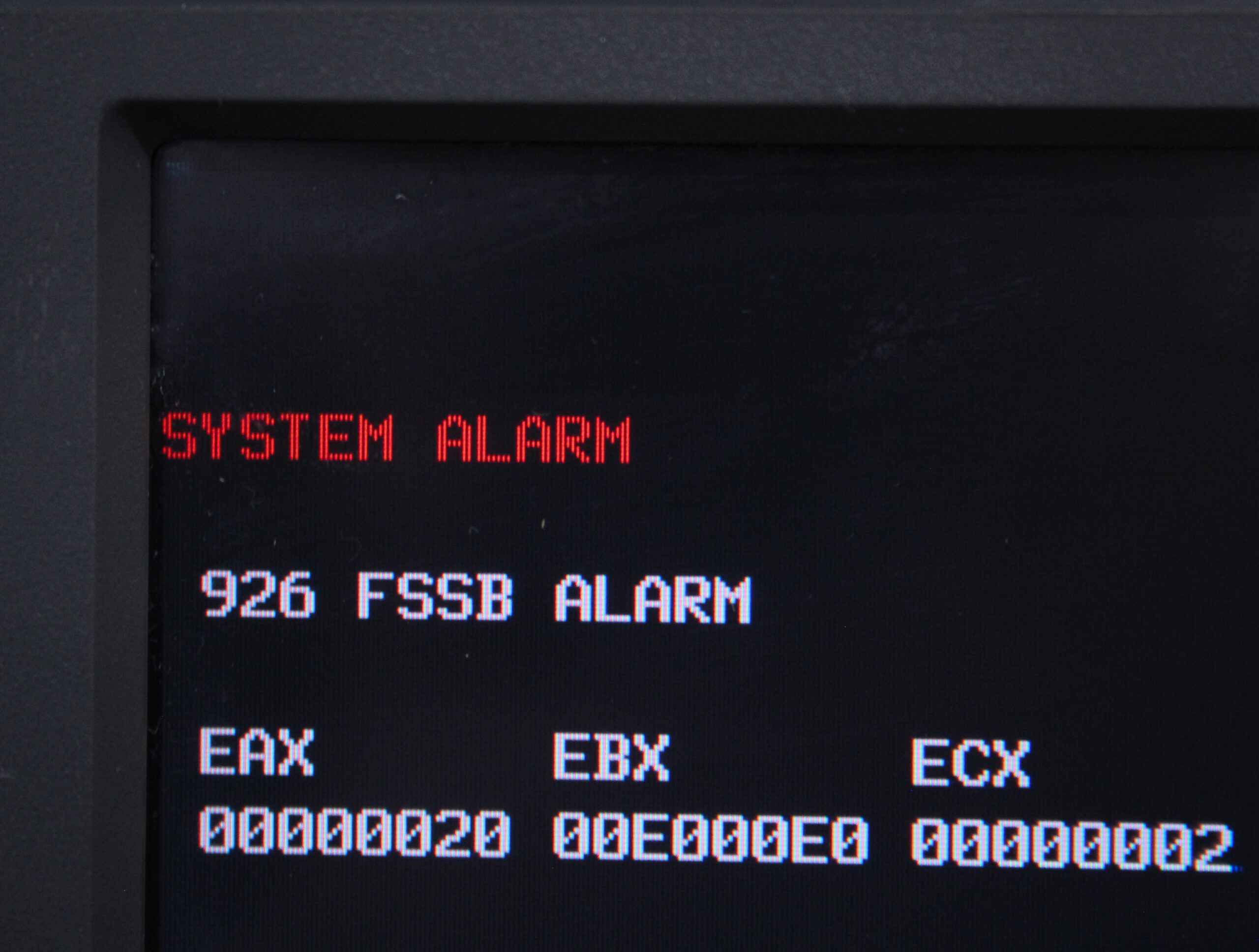

These alarms can trigger a system alarm, where the CNC machine’s control system experiences a critical failure and shuts down to prevent damage or malfunction. This “black screen of death” can be intimidating, but understanding the underlying causes and troubleshooting steps can help resolve the issue efficiently.

Fanuc Serial Servo Bus (FSSB) Overview

The Fanuc Serial Servo Bus (FSSB) is the backbone of the communication network within Fanuc CNC systems. The FSSB comprises a fiber optic cable network that links the CNC machine to its motor amplifiers. This network allows commands from the CNC machine to the amplifiers, which control the motors. Additionally, it facilitates the return of motor feedback signals to the CNC machine.

Key Components:

- Fiber Optic Cables: These cables are crucial for transmitting data within the system. Any issues with these cables, such as disconnections or damage, can result in communication loss.

- Amplifiers: These devices receive commands from the CNC and control the motor actions. They also send feedback signals back to the CNC.

- Separate Detector Unit (SDU): This unit converts signals from third-party feedback devices into a format that the Fanuc FSSB can understand.

System Alarms and Their Implications

System alarms related to FSSB problems are numbered 114 through 160. These alarms indicate specific issues within the communication network. Alarm 122, for example, signals that the FSSB was disconnected, providing a critical clue for troubleshooting.

- Main: Refers to the CNC, indicating that the problem lies within the main control unit.

- Amp and a Number: Indicates an issue with a specific amplifier, identified by its position in the FSSB chain.

- SDU and a Number: Points to an issue with a Separate Detector Unit.

- Line and a Number: Identifies the specific FSSB cable experiencing trouble.

Common Causes of Alarms U and L

Several factors can trigger CNC Alarms U and L, including:

- Fiber Optic Cable Issues: Damage or disconnection of the fiber optic cables can disrupt communication.

- Faulty Connectors: Loose or damaged connectors can prevent proper signal transmission.

- Defective Amplifiers: A malfunctioning amplifier can fail to send or receive signals correctly.

- Bad Logic Boards: The logic boards within the amplifiers or CNC can become faulty, disrupting communication.

Detailed Troubleshooting Steps

Step 1: Identify the Alarm Source

- Locate the amplifiers displaying the U or L alarms.

- Check the FSSB chain and note the position of each amplifier.

Step 2: Inspect Fiber Optic Cables

- Reseat the connectors on the fiber optic cables.

- Perform a light test: touch one end of the cable with a flashlight and compare the light levels at the other end. A dimmer light indicates a potential issue.

Step 3: Swap Components for Testing

- Swap the fiber optic cable with another to see if the problem moves.

- Swap logic boards between amplifiers of the same part number. Ensure the part numbers on the logic boards match to avoid compatibility issues.

Step 4: Check for Bad Boards

- If the first amplifier on the FSSB shows a U alarm or all drives display a dash, the issue may be with the CNC board.

Preventative Measures

Regular maintenance and inspection of the FSSB and its components can prevent alarms. Ensure fiber optic cables are clean and properly seated. Additionally, maintaining a log of system alarms and their resolutions can help diagnose future issues quickly.

No Need to Sound the Alarm: Fanuc Alarm Code Solutions

Dealing with Alarm U or L on a Fanuc CNC Servo Amplifier can be challenging, but a systematic approach can efficiently identify and resolve the issue. Always handle electronics cautiously and refer to your CNC system’s manual for specific instructions. Following these steps can minimize downtime and keep your CNC machines running efficiently and without costly delays.

To learn more about Fanuc CNC alarm codes, look no further than the experts at T.I.E. Industrial. Our team provides exceptional support services for your CNC machine systems. T.I.E. Industrial is a leading supplier of high-quality, refurbished Fanuc CNC machine replacement parts if a need arises for new equipment or parts. Call T.I.E. Industrial today!

Was this helpful?

3 / 1