Manufacturing across any sector requires precision to ensure peak performance. One missed calculation or setting, or the breakdown of a part can send your operations into a tailspin, which can be challenging to recover in terms of downtime, money, and quality. Your CNC machines play a vital role in achieving the precision necessary in the modern industrial landscape, driving successful outcomes; therefore, let’s look at the fundamentals of CNC machine parameter backup and restore – a crucial aspect ensuring your equipment’s smooth operation.

Defining Parameter Backup and Restore in Fanuc CNC Machines

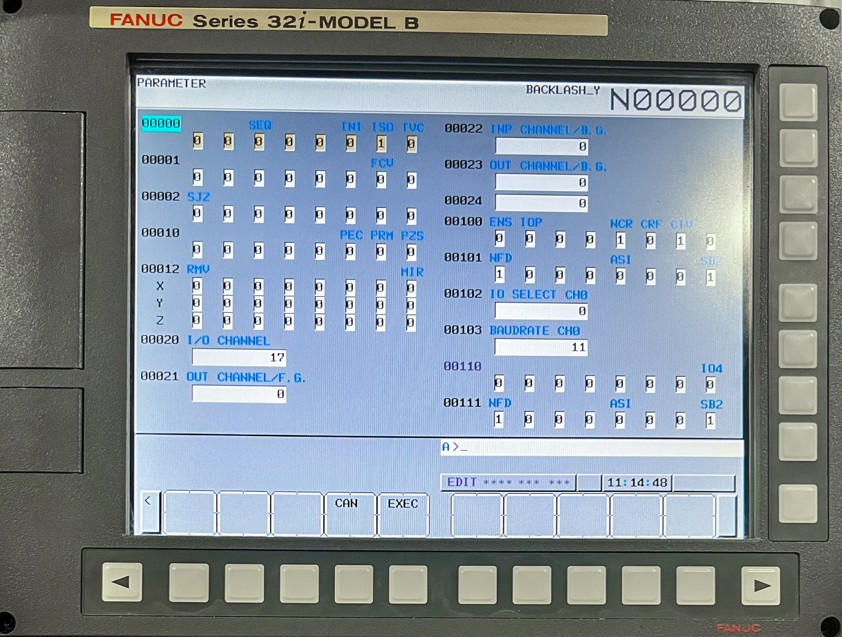

These terms refer to the processes of saving and recovering the configuration settings, known as parameters, that control the operation of the CNC system. The parameters include various machine settings such as speed, feed rates, tool offsets, axis positions, and other critical information that defines how the CNC machine functions.

Parameter Backup

Parameter backup involves creating a copy or snapshot of all the current settings and configurations stored in the CNC machine’s memory. The primary purpose of parameter backup is to safeguard crucial machine settings that have been meticulously loaded. In the event of a breakdown, maintenance, or part replacement, having a backup ensures that valuable configuration data is preserved.

The backup process typically involves selecting the appropriate backup option in the CNC control system, specifying the storage location (e.g., external device or internal memory), and initiating the backup procedure. This results in a file or set of files containing all the necessary parameters.

Parameter Restore

Parameter restore is the process of loading the previously backed-up configuration settings back into the CNC machine’s memory. The primary purpose of parameter restore is to quickly and accurately reinstate the machine settings after a breakdown, maintenance, or part replacement. This minimizes downtime and ensures that the CNC machine resumes operations with the same precision and efficiency.

To restore parameters, the operator selects the appropriate restore option in the CNC control system, specifies the location of the backup files, and initiates the restore procedure. The CNC system then reads the backup files and applies the saved parameters to configure the machine.

In summary, parameter backup and restore in Fanuc CNC machines are critical functionalities that contribute to the reliability, efficiency, and quick recovery of CNC machining operations. These processes ensure that the CNC machine can swiftly recover its optimal settings, minimizing disruptions and maximizing productivity.

The Fanuc Advantage with Parameter Backup and Restore

As a major supplier of refurbished Fanuc CNC parts, T.I.E. Industrial understands the significance of compatibility and reliability regarding parameter backup and restore. Fanuc CNC systems, such as the Fanuc Series 0i, Fanuc Series 30i, and Fanuc Series 31i, come equipped with advanced features for effortless backup and restore processes. Let’s take a look at more features.

Key Features of Fanuc CNC Parameter Backup:

Model-Specific Backup. Fanuc CNC systems, including the Fanuc Series 16i and Fanuc Series 18i, allow for model-specific parameter backup. This ensures that the backup is tailored to the exact specifications of your CNC machine, minimizing the risk of errors during the restore process.

Data Integrity. Fanuc understands the critical nature of CNC machine parameters. Their systems employ robust mechanisms to maintain data integrity during the backup process, ensuring that every parameter is accurately captured and stored.

User-Friendly Interface. Fanuc CNC systems boast an intuitive user interface, making the backup process accessible to operators with varying levels of technical expertise. The user-friendly design aligns with the needs of blue-collar professionals, enabling efficient parameter management.

Key Features of Fanuc CNC Restore

Efficient Recovery. Fanuc CNC systems excel in efficiency when it comes to restoring parameters. Whether using a Fanuc Series 21i or a Fanuc Series 32i, the restore process is designed to be swift and reliable, minimizing machine downtime.

Compatibility Assurance. Fanuc ensures that the parameters backed up from one system are seamlessly compatible with others within the same series. This level of compatibility simplifies the restoration process, allowing for smooth transitions between machines.

Outstanding Industrial Operations: Ensured with Parameter Backup and Restore

CNC machine parameter backup and restore are indispensable processes in maintaining your equipment’s optimal performance. With Fanuc CNC systems and T.I.E. Industrial’s quality refurbished parts, you can rest assured that your manufacturing operations are in capable hands. Our refurbished Fanuc CNC replacement parts are sourced and tested for optimal performance. By choosing T.I.E. Industrial, you gain access to high-quality, cost-effective solutions that keep your CNC machines running at peak efficiency.

Explore our CNC machine inventory, including parts for the Fanuc Series 21i and Fanuc Series 31i, and learn more about how the backup and restore processes are invaluable to your overall operations. Contact T.I.E. Industrial and experience the reliability and precision our refurbished Fanuc CNC machines and replacement parts bring to your factory floor.

Was this helpful?

0 / 2